To view the original article, please click here.

MRF robotics firm says it can offer detailed EPR information to brand owners.

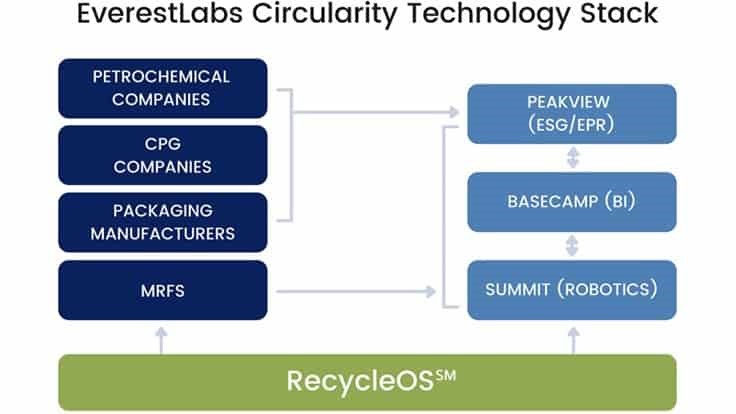

Fremont, California-based EverestLabs has now made available RecycleOS, which it calls “the first artificial intelligence (AI)-enabled recovery-to-reuse operating system that helps material recovery facilities (MRFs) recover more recyclable objects and enables consumer packaged goods (CPG) manufacturers and package manufacturers to use more recycled content.”

EverestLabs says features of the OS allow CPG companies and petrochemical companies who produce plastic to “excel at environmental, social and governance (ESG) initiatives and [assist in] meeting extended producer responsibility (EPR) goals.”

The technology firm says RecycleOS is the culmination of nearly four years of R&D, including consultations with MRF operators, CPG companies, packaging manufacturers and government entities.

EverestLabs says a United States Environmental Protection Agency study determined that in 2018 consumers and businesses sent 53.9 percent of generated packaging and containers to MRFs for recycling. However, a considerably smaller percentage is recovered, reprocesssed and reused in manufacturing, says EverestLabs.

“Until now, a solution did not exist to provide visibility into the number of recyclables being lost to landfills,” states the firm. “Accurate measurement will ultimately be a critical factor in decreasing those losses.”

RecycleOS incorporate the following, says EverestLabs:

1) Summit Robotics, a robotic cell designed to deliver a 49 percent increase in recovery for MRFs compared with some robots of earlier vintage;

2) Basecamp, which is designed to gather data on every conveyor line “for proactively improving plant operations” and generating higher revenue; and

3) PeakView, which EverestLabs describes as an ESG/EPR system of record for CPG companies, packaging manufacturers, petrochemical companies and MRFs so they can measure and track their goals across their operations.

“To date, there has been no solution to track and ensure that every object is recycled, recovered and reused in manufacturing,” says JD Ambati, founder and CEO of EverestLabs. “RecycleOS is the first solution that connects MRF operators, CPG companies, packaging manufacturers and petrochemical companies with real-time actionable data. We are committed each day to recover more recyclable materials in a cost-effective way and make circularity a reality while slowing climate change. Our ultimate goal is that no recyclable is left behind.”

Customers who have implemented RecycleOS include Alameda County [California] Industries, Rethink Waste, the City of Sunnyvale [California], Sojitz-Japan and two of the 10 largest waste management companies in the U.S., according to EverestLabs.

“EverestLabs data has helped us evaluate the performance of our recent MRF equipment investments and will inform where we add sorting equipment,” states Hilary Gans, senior operations and engineering manager at San Carlos, California-based Rethink Waste. “We are now considering EverestLabs to help us evaluate the composition of our residue and trace problem packaging back to individual producers.”

Says Jeff Dolbert, director of operations at Bay Counties SMaRT, a division of Bay Counties Waste Services (serving Mountain View, Palo Alto and Sunnyvale, California), “We elected to install EverestLabs robots because of their small footprint, ease of installation, and recovery of tough objects like HDPE milk jugs and in tight locations. We can’t work with the [earlier] robots because they are just too big and expensive. Also, EverestLabs’ AI object recognition is the best we’ve seen.”

“These customers are trailblazers for implementing our solutions to truly make a difference in MRF operations [and to] improve producer responsibility and increase circularity,” says Don Gambelin, head of sales at EverestLabs. “It is the feedback and input from these organizations that enabled us to build this first solution that addresses the ‘cradle to rebirth’ of packaging. As we work with more global companies, we will continue to localize our solutions and improve further.”